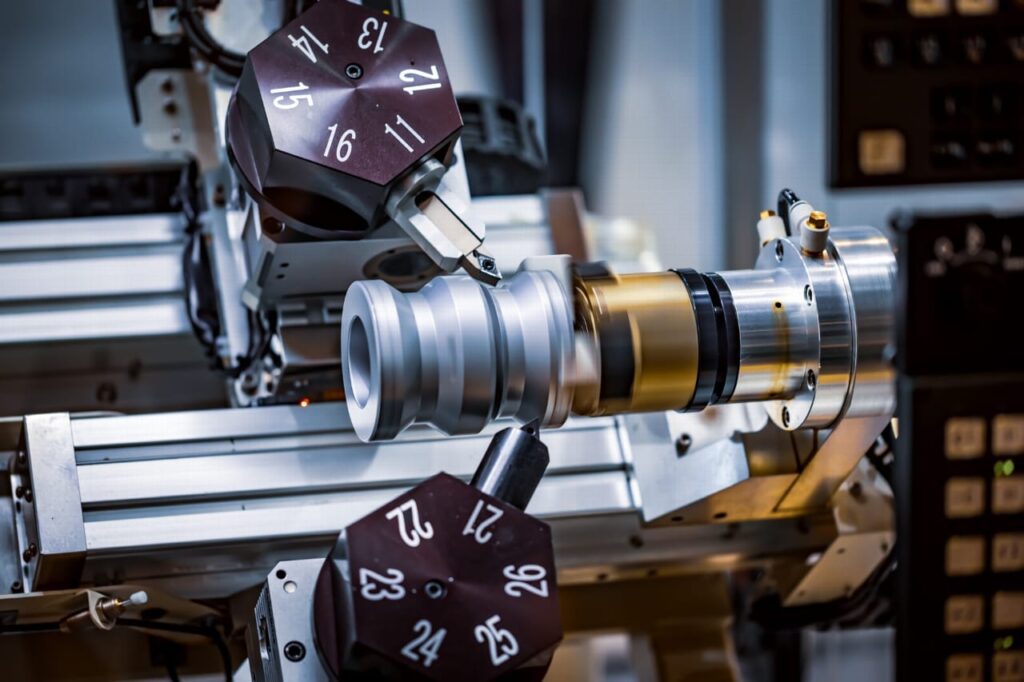

When machinery precision matters, choosing the right ball screw manufacturer becomes a critical decision for industrial operations. Ball screws transform rotational motion into linear movement with minimal friction, making them essential components in everything from CNC machines to aerospace applications. But, not all manufacturers deliver the same quality and service. Here’s what you should consider when selecting a partner for your ball screw needs.

Industry Experience and Technical Expertise

A manufacturer’s longevity in the industry often reflects their ability to consistently deliver quality products. Look for companies with:

- Extensive experience working with various industries

- In-house engineering teams that understand application-specific challenges

- Demonstrated knowledge of materials science and mechanical design principles

A Trusted Ball Screw Manufacturer like Dynatect has built their reputation through decades of solving complex motion control challenges across diverse industrial environments. This experience translates into practical advice that can save you from costly mistakes.

Manufacturing Capabilities and Quality Control

The precision of your ball screws directly impacts your equipment’s performance. Reliable manufacturers maintain stringent quality control protocols throughout their production process.

Ensure your manufacturer offers comprehensive testing that verifies critical specifications like lead accuracy, preload consistency, and surface finish quality. The best partners will provide detailed documentation of these tests and maintain traceability for all components.

Dynatect’s approach to quality control includes multiple inspection points during manufacturing, ensuring that each ball screw meets exact specifications before shipping.

Customization Options

Standard catalog items rarely provide optimal performance for specialized applications. A manufacturer worth partnering with should offer customization services tailored to your specific requirements.

Consider whether the manufacturer can provide modifications to:

- Lead and diameter specifications

- End machining configurations

- Material composition for challenging environments

- Surface treatments for enhanced durability

The ability to create custom solutions demonstrates a manufacturer’s technical capabilities and commitment to solving your unique challenges rather than simply selling catalog items.

Support Services and Maintenance Options

Ball screws represent a long-term investment, and the best manufacturers stand behind their products with comprehensive support services. Look for providers offering:

- Repair and reconditioning programs that can extend component life

- Preventative maintenance recommendations specific to your application

- Technical support from engineers familiar with your industry

When a critical ball screw fails, having a relationship with a manufacturer that offers expedited repair services can dramatically reduce downtime costs. Dynatect’s service teams specialize in rapid response that keeps production lines running.

Supply Chain Reliability

Recent global disruptions have highlighted the importance of supply chain stability. Evaluate manufacturers based on their:

- Inventory management practices for common components

- Domestic manufacturing capabilities

- Transparent lead times and delivery commitments

Manufacturers with robust supply chains can deliver consistent quality without unexpected delays that impact your production schedule.

The Value of Partnership

The most reliable ball screw manufacturers view themselves as partners in your success rather than simply component suppliers. They invest time in understanding your application requirements and offer solutions that maximize performance and lifespan.

By selecting a manufacturer like Dynatect that excels in these critical areas, you’re not just purchasing precision components—you’re gaining a technical ally dedicated to keeping your equipment operating at peak efficiency.